Follow Us:

How to Extract Lutein from Marigold

Lutein is a yellow plant pigment belonging to the xanthophyll family of carotenoids and widely present in marigold flowers. Lutein is an effective antioxidant that may be utilized in foods as a natural coloring pigment and functional feed ingredient.

Beyond its visual appeal, marigold extract holds a secret treasure. As a natural feed additive, lutein fits the trend of “antibiotic reduction and replacement” in the feed industry, especially in poultry and aquatic feed, where demand has grown significantly. Customers are more concerned about its cost-effectiveness, stability and traceability. Greenagribio needs to improve product competitiveness through process optimization (such as microencapsulation technology). This blog post tackles on what are the benefits and extraction methods of marigold flower extract for the well-being of our beloved animals.

What is Marigold Flower Extract?

Derived from the vibrant petals of the marigold flower (Tagetes species), marigold extract is renowned for its potent phytonutrients, including lutein and zeaxanthin. These compounds offer a spectrum of health benefits for animals, making marigold extract a valuable addition to their diet and care routines.

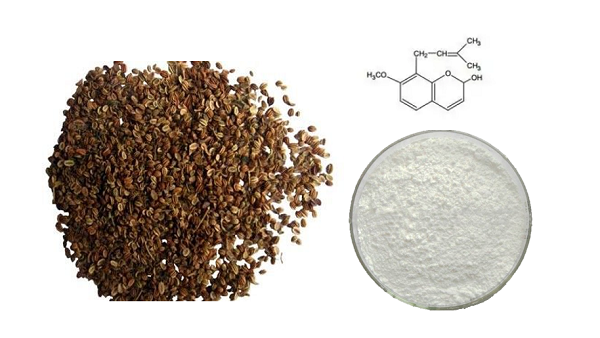

Extract Lutein from Marigold Manufacturer Process

- Raw Material Selection: We select fresh marigold flowers (Tagetes erecta) based on high lutein content.

- Flower Harvesting & Drying: Workers harvest the flowers at full bloom and dry them under controlled conditions (e.g., shade drying or low-temperature drying) to preserve lutein content.

- Grinding & Milling: We grind the dried flowers into a fine powder to increase the surface area for extraction.

- Pigment Extraction:

- Solvent Extraction: We treat the powder with organic solvents (e.g., hexane, ethanol, or acetone) to extract lutein and other carotenoids.

- Supercritical Fluid Extraction (SFE): Use CO2-based extraction under high pressure for a solvent-free, high-purity yield.

- Filtration & Concentration: We filter the extract to remove impurities and concentrate it by solvent evaporation or vacuum distillation.

- Saponification: We treat the crude extract with an alkaline solution (e.g., potassium hydroxide) to remove esterified forms and enhance bioavailability.

- Purification & Crystallization: The lutein-rich solution is purified using chromatography or crystallization techniques.

- Drying & Powder Formation: The purification process dries the lutein (e.g., spray drying) and converts it into a powder form for commercial applications.

- Quality Control & Packaging: A quality control team tests the final lutein extract for purity, potency, and contaminants before packaging.

- Detection: HPLC detection of lutein content to ensure compliance with feed additive standards.

| Item | Specification |

| Product Name | Feed Grade Lutein (Marigold) |

| Source | Marigold (Tagetes erecta) |

| Appearance | Orange to reddish-brown powder |

| Lutein Content | ≥ 5%, 10%, 20% (as per requirement) |

| Zeaxanthin Content | ≤ 5% |

| Carrier | Corn starch, antioxidants, or gelatin |

| Particle Size | 80-100 mesh |

| Loss on Drying | ≤ 5% |

| Solubility | Insoluble in water, dispersible in oil |

| Heavy Metals (Pb) | ≤ 10 ppm |

| Arsenic (As) | ≤ 2 ppm |

| Microbial Limits | Total Plate Count ≤ 1000 CFU/g |

| Yeast & Mold | ≤ 100 CFU/g |

| Salmonella | Negative |

| E. coli | Negative |

| Storage Conditions | Cool, dry place, away from direct sunlight |

As a Marigold Extract Lutein Supplier Greenagribio are pleased to offer a MOQ 1-25kg, with the flexibility to customize orders based on your specific requirements. Whether you need smaller quantities for research, formulation, or testing, or larger quantities for commercial production, Our can accommodate your needs.

Marigold Extract Lutein: Dosage, Safety, Uses in Animal Feed

Dosage

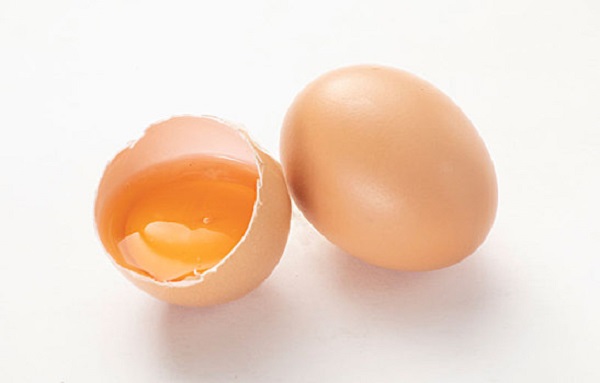

- Poultry: 10-30 mg/kg of feed for optimal yolk pigmentation.

- Aquaculture: 50-100 mg/kg of feed for fish and shrimp pigmentation.

- Pet Food: 5-20 mg/kg for eye health support.

- Livestock: 10-50 mg/kg for antioxidant benefits.

Safety

- Lutein from marigold is generally recognized as safe (GRAS) when used within recommended levels.

- Overuse may cause excessive pigmentation in egg yolks and fish skin but has no known toxic effects.

- Should comply with regulatory limits in different countries.

Uses

- Poultry Feed:

- Enhances yolk color in eggs, increasing their market value.

- Improves the skin pigmentation of broilers, making them visually appealing to consumers.

- Aquaculture Feed:

- Used in fish feed, particularly for salmon and shrimp, to enhance pigmentation and improve visual quality.

- Pet Food:

- Pet food ingredients suppliers support eye health and immune function in dogs, cats, and ornamental birds.

- Livestock Feed:

- May serve as an antioxidant and immune booster in dairy and cattle feed formulations.

Greenagribio feed manufacturer are tested by accredited third party labs in the USA to ensure their identity, purity and potency. To receive a copy of these test results or any other, please fill out the COA.

Also See

FAQs of Feed Customers to Bulk Lutein Extracts

1. Consistent Quality & Stability

Customers require standardized lutein content with minimal degradation over storage time.

2. High Bioavailability

Feed formulators prefer free-form or microencapsulated lutein for better absorption.

3. Regulatory Compliance

Greenagribio Supplier regulatory standards (e.g., EU, FDA, FAMI-QS) to ensure product safety.

4. Cost-Effectiveness

Feed manufacturers seek competitively priced lutein that balances cost with pigmentation efficacy.

5. Solubility & Mixability

Water-dispersible or oil-soluble forms are required based on different feed applications.